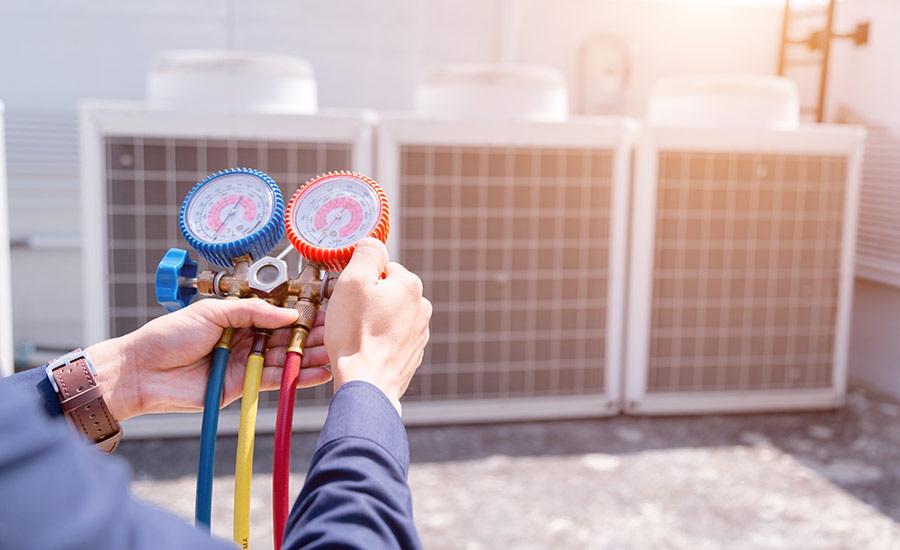

Now is the Time for Spring HVAC Inspections

Routine maintenance can help extend the efficiency of your commercial HVAC system. It’s also essential to maintaining good indoor air quality for your employees and/or customers. Experts recommend having your equipment inspected and serviced before the start of the heating and cooling seasons. Doing so will ensure it stays efficient all-year-round. Now is the time to